In our previous article, we took a comprehensive look into the world of electric nail drills, diving into their primary features and optimal utilization methods. Today, we’re setting our sights deeper, pulling back the curtains on the intricate internals of a nail drill handpiece, coupled with a detailed guide on its care and maintenance.

Before diving into maintenance, it’s crucial to identify prevalent challenges:

The remedy? Systematic cleaning, lubrication, and timely maintenance!

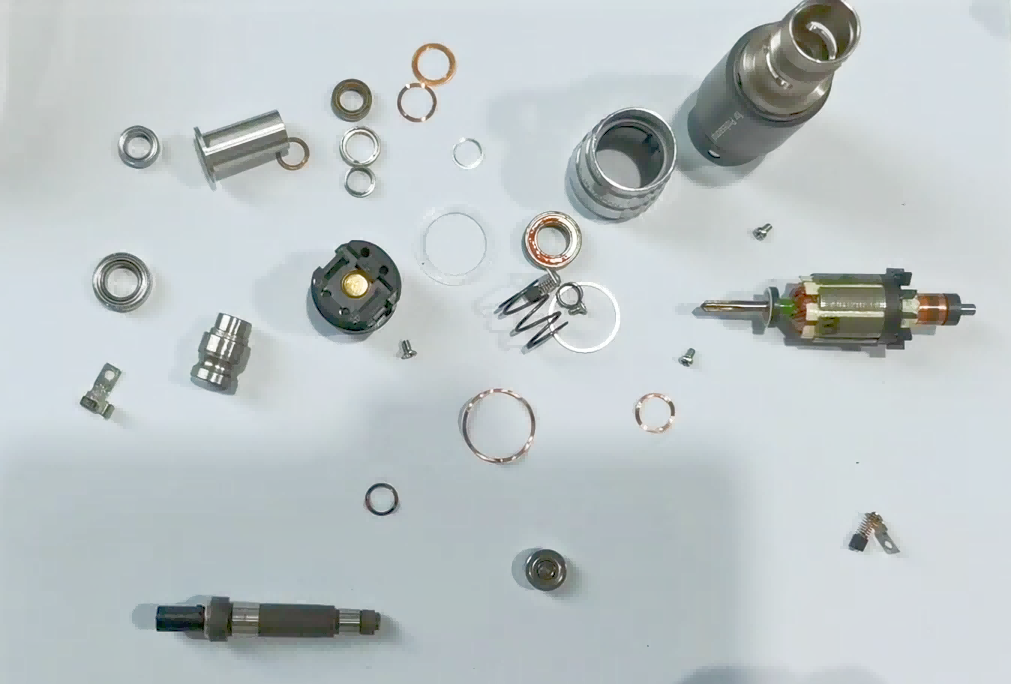

While the design and construction of a nail drill handpiece might differ across brands. For example, the following two pictures, the first one is the construction of the most common handpiece parts on the market, the second one is the high-end customized models of our customers, just from the number of parts, you can see that the workmanship of the product is very different.

There are fundamental components shared amongst most:

And then, based on the unique design quirks of different brands, some handpieces might come equipped with additional cooling systems or even gears to enhance functionality.

Supplies:

Procedure:

Persisting issues post-cleaning might be indicative of a more profound problem, like the need to replace components such as the motor or the bearings. That’s why we went a brief look at handpiece construction at the outset.

For the professionals out there, especially those running bustling salons, remember: cleanliness isn’t just about performance; it’s about ensuring your clients’ safety. Making it a routine to clean those nail drill bits and other attachments after each use isn’t just best practice; it’s a hallmark of a professional.

The essence of this guide is to highlight the significance of understanding and maintaining your nail drill handpiece. The insights provided steer clear of complex electronic or mechanical fixes but emphasize cleaning and basic troubleshooting. Adopting these best practices ensures not only impeccable service quality but also the safety of your clientele. Here’s to mastering the art of nail drill maintenance and a flourishing nail art journey!

Social Sharing: If you found this guide valuable, please consider sharing it on your favorite social media platforms. Your support helps others get access to this crucial information!

Feedback and Comments: We truly value your thoughts and feedback! If our website’s setup permits, kindly leave your comments, questions, or experiences below.

16 Years

Experience

12 Months

Warranty

Monday - Sunday

24/7 Customer Support

Be the first to know about special offers, new innovations and more.